Understanding Wear Limits

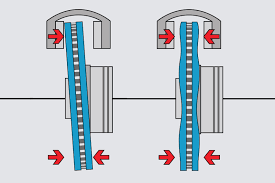

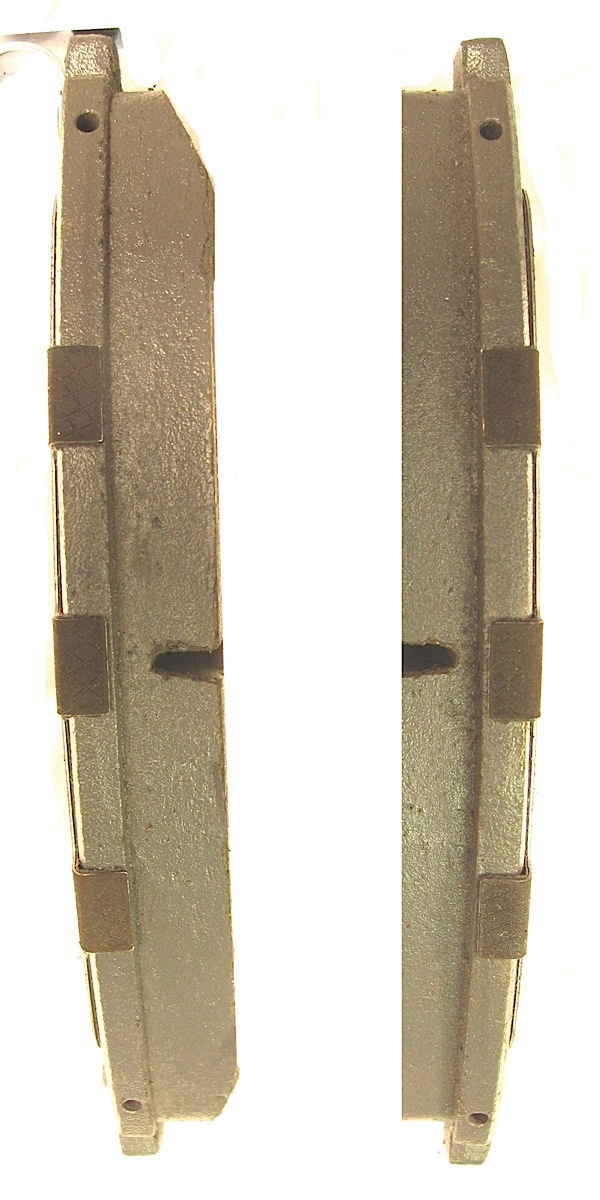

Brake pads typically consist of several layers:

- Friction material (10-12mm when new)

- Adhesive layer

- Backing plate (steel)

- Some include shims or wear indicators

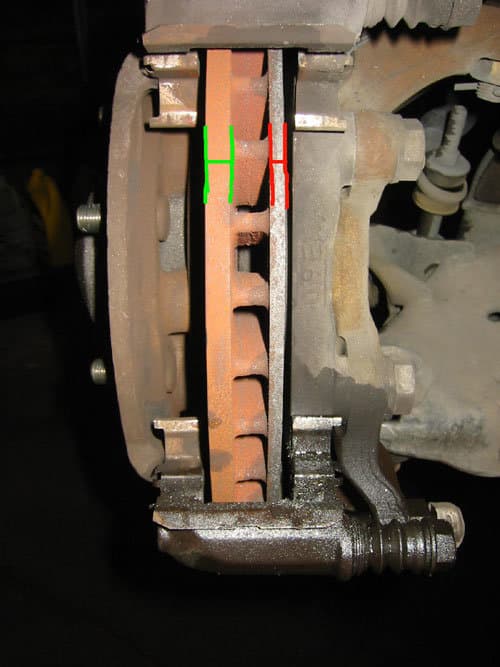

The minimum safe thickness before metal-to-metal contact occurs depends on pad design, but general guidelines are:

New: 10-12mm (excellent stopping power)

Good: 6-8mm (normal wear range)

Monitor: 4-5mm (schedule future replacement)

Replace Soon: 3mm (wear indicators may contact)

Replace Now: 2mm (urgent - risk of rotor damage)

Dangerous: 1mm (metal contact imminent)

Factors Affecting Brake Pad Lifespan

While manufacturers provide general mileage estimates, actual pad life varies dramatically based on:

- Driving Style: Aggressive drivers may wear pads 2-3x faster than conservative drivers. Frequent hard braking generates excessive heat that breaks down friction material.

- Environment: City driving with constant stop-and-go traffic wears pads much faster than highway cruising. Mountainous terrain also increases brake usage.

- Vehicle Weight: Heavy SUVs and trucks wear pads faster than compact cars due to increased momentum requiring more braking force.

- Pad Material: Organic pads wear fastest but are quiet. Ceramic lasts longer but costs more. Semi-metallic offers a balance but generates more dust.

- Passenger/Cargo Load: Regularly carrying heavy loads or multiple passengers accelerates wear.

- Weather Conditions: Frequent driving in rain or snow can reduce pad life due to moisture exposure and road debris.